…

…

INTRODUCING 906 ENGINEERING’s NEW

…

…

ELECTRONIC SWING DOOR OPENER with a FLEXIBLE DRIVE LINK that is RETROFITTABLE TO MOST DOOR CLOSERS

…

Sometimes in business, success is reached by opening new doors of opportunity. Here at 906 Engineering we have taken that philosophy to heart. Our engineering team has developed what we think is a better way to open doors; a safer way, an easier way and more economical way. The patented ideas that follow are the sole property of 906 Engineering Corporation, if you have any interest in this new technology, please contact us.

…

Disclaimer: 906 Engineering has no affiliation with LCN, Yale, Norton or any other manufacturer of door closers. The images of door closers shown in this literature are a generic representation of the most popular/standard style of door closers currently used.

Note: This literature will talk a lot about door “closers” & door “openers.” The door closer is a device that allows a swing door to open when manually pushed, then closes the door once it is release. The door opener is a device that uses electronics to open a swing door automatically, then closes the door after a period of time.

…

Quick Background

…

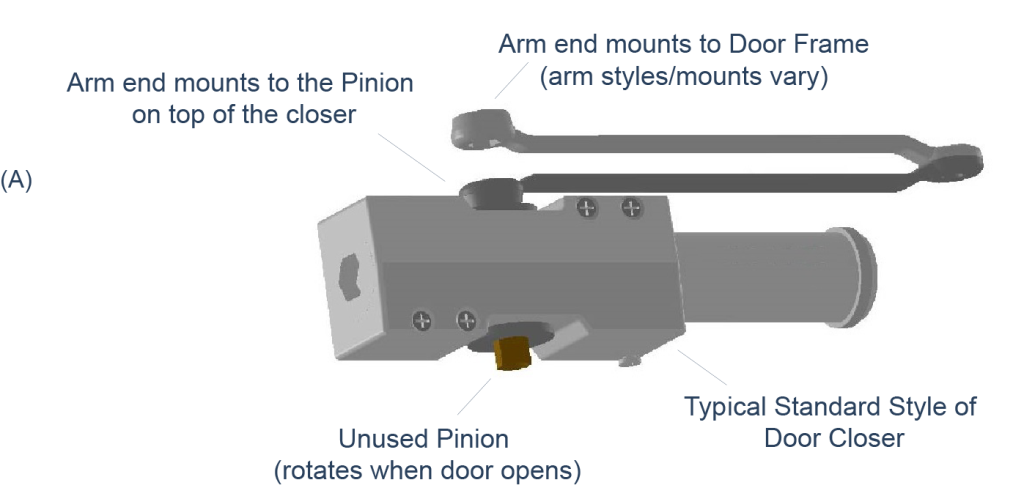

Diagram A shows an image of a typical style of door closer. We consider this style to be the standard when it comes to door closers used on “manual opening” swing doors. These closers have been around for years, they are currently used everywhere and they rarely fail. They are true workhorses when it comes to getting the job done.

…

…

Typically, these closers would have a cover over them and all you would see are the arms protruding from the top of a box. The closers are mounted to the door and the other end of the arms mounts to the door frame. Notice how the arm attaches to the closer on a pinion that rotates. This pinion runs all the way through the closer body so that the closer can be flipped to work on a door hinged on the left or on the right. These closers can be mounted on the Push side of the door, or the Pull side of the door, or on the push side door jamb instead of mounted to the door. These closers are very versatile, but in every situation there is always an unused pinion on the opposite side.

…

Electronic Opener Problem #1

…

With current electronic swing door openers, motors and metal gears typically control the powered operation. These work fine during electronic operation, until an issue arises. Over time, parts wear out and metal gears can shatter under pressure. If metal fragments get into gears it can lock them up causing the door to be locked into any position (locked open, locked closed, locked half-way open). This requires maintenance to replace the broken parts or replace the entire opener which all could be very costly.

Many times when an automatic swing door opener is installed, it is to assist people that may be dealing with physical issues that make opening a door difficult. But, in high traffic applications, most people using the door, don’t have any physical issues. They will try to manually open these doors if that is an option. If you have ever gone to open a door in a store or office and it seems a lot harder to open then you thought it would be, it may be because of an automatic door opener that is installed on it. Even though you are not using the electronics to open the door, all those gears in the opener are turning even when you open the door manually. This makes the door a lot harder to open and it puts extra wear on all the mechanical parts of the opener.

…

Solution #1

…

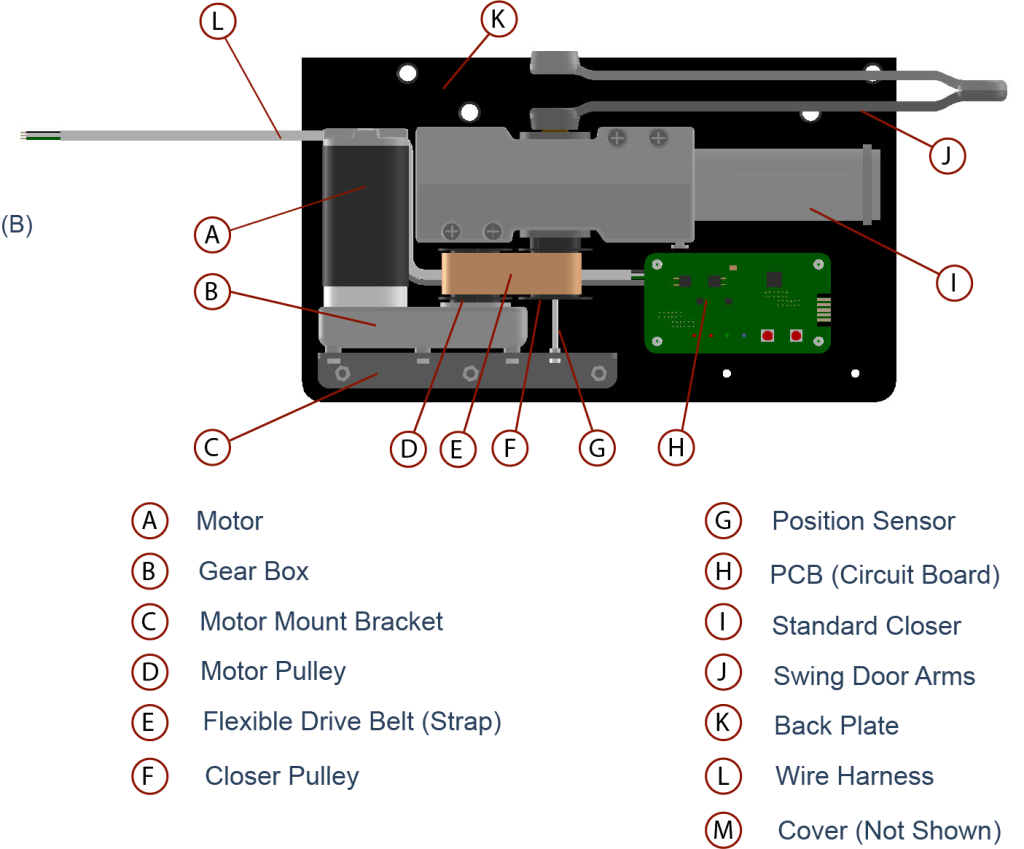

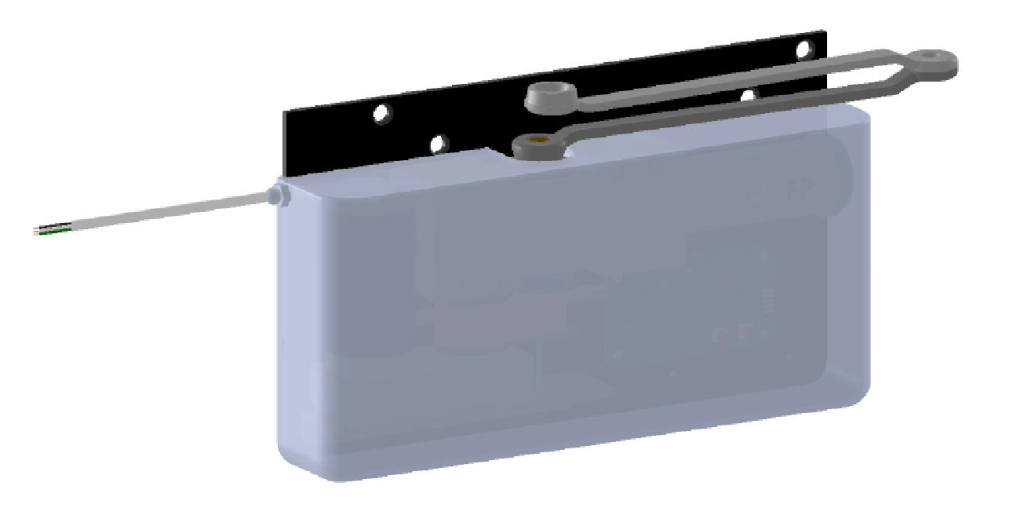

Our team at 906 Engineering has come up with a solution by replacing the metal gears typically used in electronically operated swing doors with a flexible drive link that creates a smoother operation which is also more cost efficient because it negates several parts needed in current designs. See diagram B below for a basic design of our electronic opener and a basic description of the parts used in our design. We call it the “FLEX CONNECTED” electronic swing door opener.

…

…

The Flexible Drive Link

…

The Flexible Drive link is where all the magic happens. This link could be a chain, a rope, a rubber or leather belt or a strap. We have found that using a strap, much like the straps used in ratchet straps are the best solution because of their strength and durability. These flexible drive links also have the ability to flex under stress, which most metal gear openers do not.

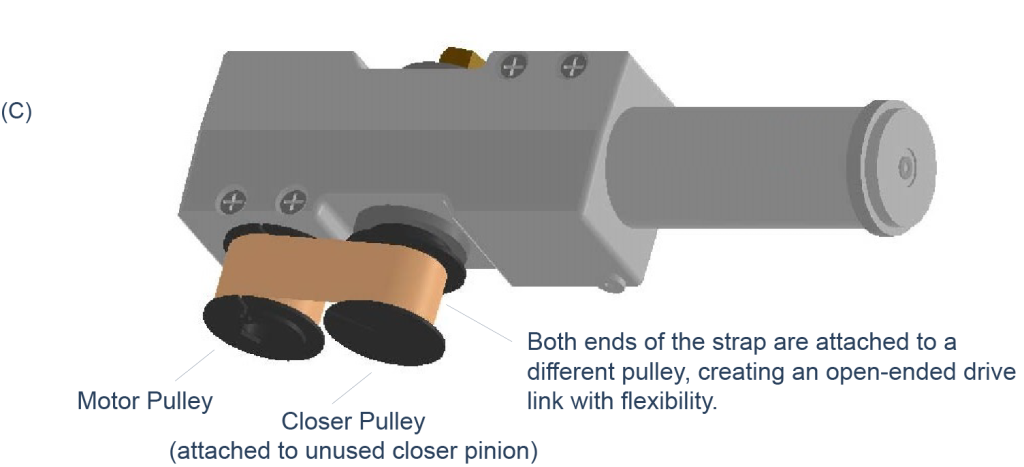

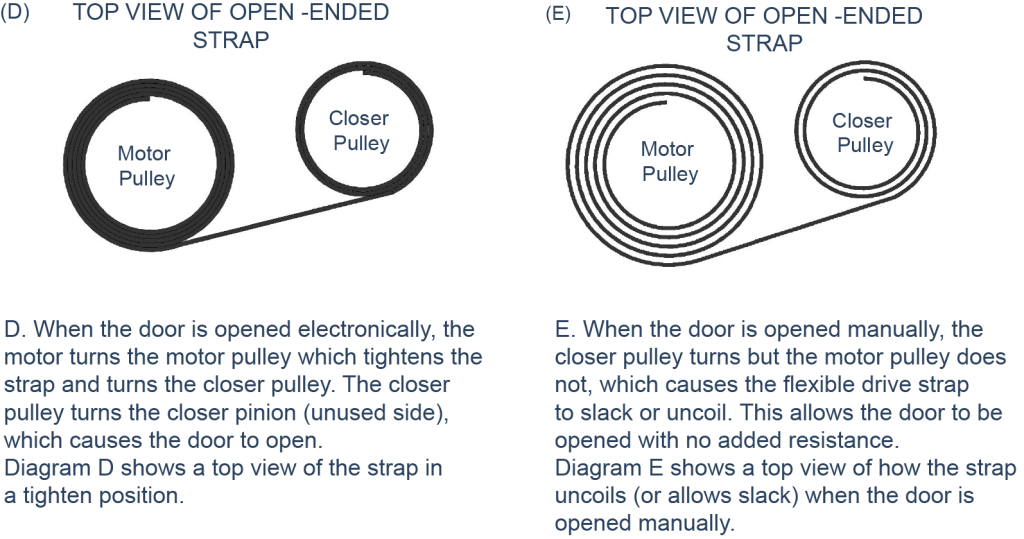

But, the real key to this idea is not just using a flexible drive belt, it is using an open-ended drive belt (See Diagram C). By using an open-ended flexible drive belt, the strap pulls tight when the door opener is activated and the door opens. When the door closes, the hold of the motor releases and the door closer goes to work closing the door. Plus as an added bonus, when opening the door manually, the open ended strap just goes slack and the door opens just like it would if no electric door opener was installed. Yes, besides the added weight of the opener, there is zero resistance added to opening the door manually and zero wear on the mechanical parts of the opener when manually opening the door.

…

…

…

Advantages: FLEX CONNECTED Swing Door Opener

…

- Zero resistance when opening & closing manually.

- Less wear on mechanical parts like the motor and gear box.

Note: The FLEX CONNECTED opener does use some metal gears, but the flexible drive link separates these parts from the manual operation of the door, thus protecting these parts from unnecessary wear. - Less maintenance/Longer life with less unnecessary wear.

- Cost savings. Fewer, more inexpensive parts needed.

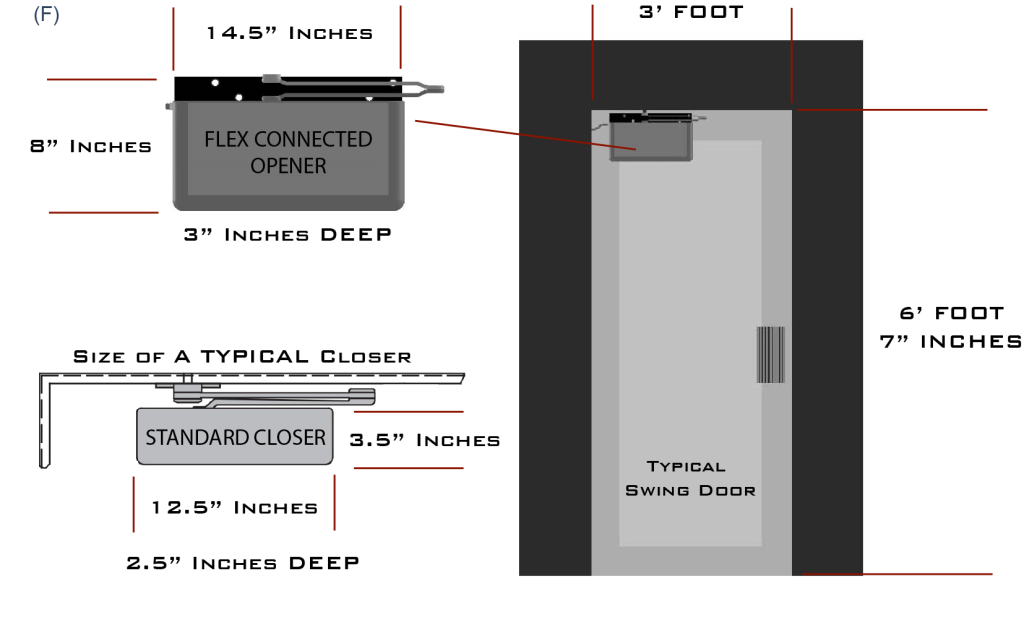

- Space savings. Our opener is 14.5” wide, 8” high and 3” deep. Which is smaller then a lot of the more powerful, industrial openers on the market.

- Easy to install. It is about 19-20 lbs., which is lighter then a lot of the more powerful, industrial openers on the market.

- Double Swing Doors can be programmed to work in unison.

- Mounts to door or door frame (above door). Anywhere a standard closer can be mounted, most likely our opener can be installed.

- Never Locked In. The FLEX CONNECTED door opener allows you to open the door manually like normal. In case of damage to the opener, a fire or a power outage, the door will always open like a normal door.

…

- High Use Environments. We have done extremely high volume, in-house testing with this flexible drive link technology, and we have yet to see a failure.

- Interior or Exterior Doors. Our door opener does not care. The flexible drive belt offers smooth, powerful openings, and the installed standard closer provides reliable closing, just like it has for years on interior or exterior doors.

- Electronic Gate Opening is another market that our patented flexible drive link technology would be a perfect fit for.

- Wireless/Rechargeable. Could be designed to be wireless with removable, rechargeable batteries.

- Accessories like actuating buttons, remote controls & sensor opening products can all be made to work seamlessly with this technology.

- Price. If you look at electronic door opener pricing, you will see some very affordable options. But look closely, because most of these low cost openers are strictly for light duty inside doors. The FLEX CONNECTED opener has commercial grade strength at affordable electronic door opener pricing.

…

Size: FLEX CONNECTED Electronic Door Opener

…

Diagram F shows the size of the FLEX CONNECTED door opener compared to the typical size of a swing door. It also shows the size of a typical standard closer. As shown, the FLEX CONNECTED opener is not that much bigger then the closer that is required to manually open & close the door.

Note: The FLEX CONNECTED opener shown in this product literature, is the first generation design for this product. 906 Engineering is current developing a more slimmed down design which will make for a more compact unit.

…

…

Electronic Opener Problem #2

…

When installing an electronic swing door opener, in many instances, the installation is happening on an existing door that already had a closer in place. Maybe you have a manually opening door and you want to have an electronic opening option, so you purchase an electric opener. The first thing you have to do, in most situations, is remove the installed closer. In many cases these removed closers are discarded (trash).

As stated before, these standard closers are everywhere, they are reliable & durable, but they are also kind of expensive. Retail pricing can be as low as $125-$250, but some of the more quality, commercial grade closers range from about $400-$600. So, to take one off and deposit it in the garbage is a costly waste.

…

Solution #2

…

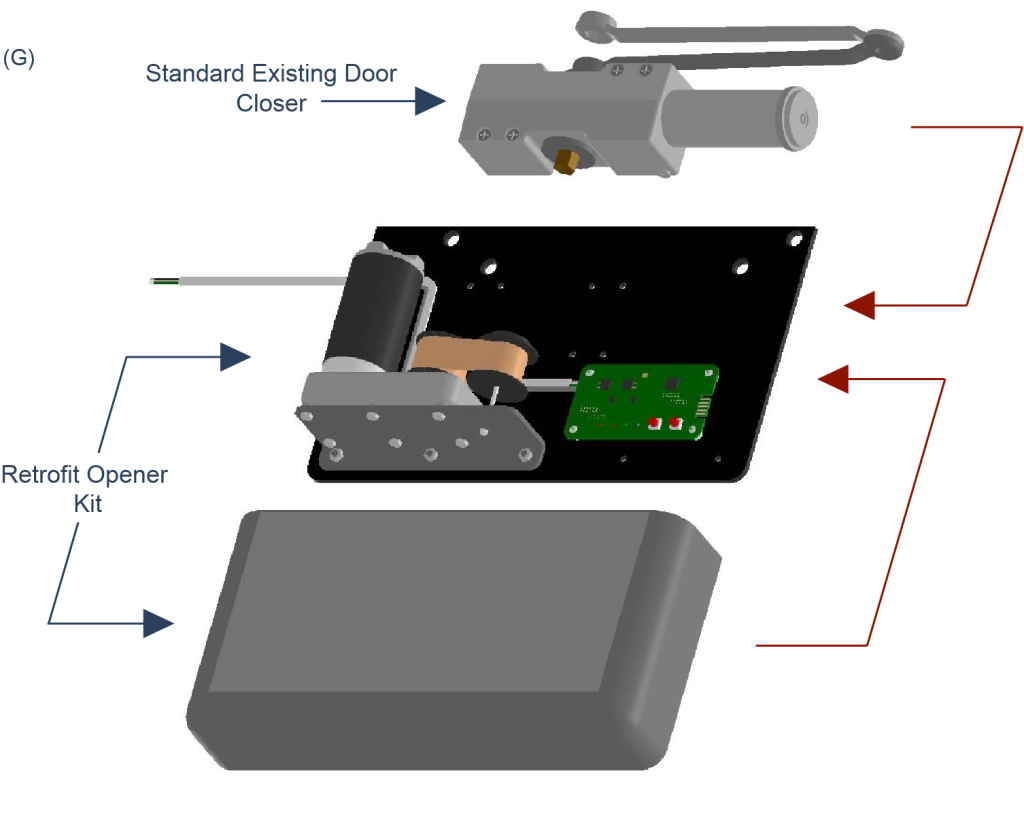

Our team at 906 Engineering not only had cost saving in mind when we developed the FLEX CONNECTED swing door opener, it was also designed to be retrofittable to doors that already had a standard closer installed. By creating a separate FLEX CONNECTED retrofittable opener kit that has everything needed except the closer (Diagram G), that would allow customers to save money by re-using their existing closer. These retrofittable kits are easy to install. Just remove the existing closer (which would have to be done for most opener installations) and install it to the back plate. New mounting screws are provided and the back plate already has threaded holes that line up with the most popular closers. Instructions are also provided. They explain all the steps, including directions on setting up the connection between the unused pinion of the closer and the closer pulley.

…

…

Advantages: FLEX CONNECTED Retrofittable Swing Door Opener

…

- Price. Without having to purchase the closing portion of the FLEX CONNECTED swing door opener (by using an existing closer), the price is significantly lower.

- No Waste when re-using the existing closer.

- Retrofittable Kits are NOT difficult to install. Just a few extra steps.

- All The Same Advantages for the FLEX CONNECTED opener listed earlier, still pertain to this retrofittable kit.

…

ELECTRONIC SWING DOOR OPENER with a FLEXIBLE DRIVE LINK that is RETROFITTABLE TO MOST DOOR CLOSERS

…

Questions, Interest? Contact Us

…

The flexible drive link technology described and shown above is patented technology owned by 906 Engineering. We at 906 Engineering, think that this technology gives our opener product line a distinct advantage to all other opener product lines available at this time. If you have any interest in this technology or any interest in our FLEX CONNECTED product line, please let us know. Your feedback is very important to us and we will always appreciate it.

With any questions or comments about this technology/product line; contact us (below), we would love to hear from you.

…

Contact: James Perales (906) 458-1461

james.p@906engineering.com

©2024 906 Engineering Corp

…

…

Disclaimer: 906 Engineering has no affiliation with LCN, Yale, Norton or any other manufacturer of door closers. The images of door closers shown in this literature are a generic representation of the most popular/standard style of door closers currently used.